Several common forms of flange sealing surface

The commonly used sealing surface forms of medium and low pressure flanges are flat, concave-convex surface and tongue and groove surface.

1. Flat flange

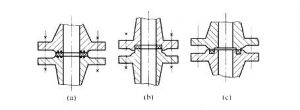

The sealing surface of this kind of flange is a smooth plane, and sometimes there are two concentric circular grooves (commonly known as water lines) with a triangular interface on the sealing surface. As shown in Figure 3-1(a).

Sealing surface of flat flange

Gaskets suitable for flat flanges include various non-metallic flat gaskets, coated gaskets, metal-wrapped gaskets, and spiral wound gaskets (with inner ring or outer ring or inner and outer ring at the same time). Because of its simple structure, convenient processing, and convenient construction of anti-corrosion lining, it can be used when the nominal pressure is p<2.45MPa. It is especially suitable in places where the pressure is below 0.588MPa and the temperature is not high. However, the contact area between the sealing surface and the gasket is large (especially the wide-face flange for pipelines), and the required compression force is large. The gasket should not be positioned during installation. . After pre-tensioning, the gasket is easy to stretch or move to both sides. Therefore, such as PTFE and other gaskets with a small friction coefficient, this type of sealing surface is not suitable. In addition, if spiral wound gaskets are used, in order to reuse gaskets, no triangular grooves are machined on the sealing surface.

2. Concave and convex flange

The flange sealing surface is composed of a concave surface and a convex surface, and the gasket is placed in the concave surface, as shown in Figure 3-1(b). The applicable gaskets are: various non-metallic flat gaskets, coated gaskets, metal-wrapped gaskets, spiral wound gaskets (basic or with inner ring), metal corrugated gaskets, metal flat gaskets, and metal tooth-shaped gaskets.

Compared with the flat flange, the gasket in the concave and convex flange is not easy to be extruded, and it is easy to align during assembly. The working pressure range is wider than that of the flat flange, which is used in the occasions with strict sealing requirements. However, for equipment with high operating temperature and large sealing diameter, the gasket may still be extruded when using this type of sealing surface. For example, a heat exchanger with a pressure of 2.45MPa and a temperature of 250°C uses pure aluminum flat gaskets. According to the data provided in Table 2-2, the maximum operating temperature of pure aluminum is 425°C, and its sealing should be reliable. In fact, the heat exchanger leaked soon after it was put into operation, and it only lasted for a while after the second tightening. After parking inspection, it was found that the inner diameter of the gasket was significantly deformed. The reason is that pure aluminum has good plasticity. The yield strength at 250°C is about 15% of normal temperature, and the elongation rate is as high as 4 to 5 times. This means that the aluminum pad has serious rolling and creep phenomena at high temperatures. Therefore, the required sealing pressure cannot be maintained between the gasket and the flange surface, so the gasket material must be replaced or the tongue-and-groove flange and the concave-convex flange with two stops (such as high-pressure sealing, metal The flange surface structure used by the flat gasket) to solve the problem.

3. Tongue and groove flange

The flange sealing surface is composed of a tongue and groove surface and a groove surface, and the gasket is placed in the groove, as shown in Figure 3-1(c). Applicable gaskets include: metal and non-metal flat gaskets, metal-clad gaskets, spiral wound gaskets (basic type), etc. Like the concave-convex flange, the tongue and groove flange will not be squeezed out in the groove, the compaction area is the smallest (only 52-68% of the flat flange and the concave-convex flange), and the gasket is evenly stressed. Since the gasket is not in direct contact with the medium, the corrosion effect of the medium and the penetration effect of the pressure mechanism are minimal, and it can be used in occasions with strict sealing requirements such as high pressure, flammable, explosive, and toxic media. This kind of sealing surface gasket has good neutrality during installation, and it is difficult to process the sealing surface and replace the gasket.

4. Flanges with other sealing surface types

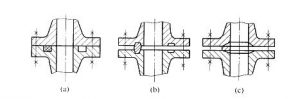

In addition to the above three sealing surface types, there are also trapezoidal groove sealing surfaces, as well as special sealing surface types when O-rings and lens pads are used. See Figure 3-2.

Figure 3-2(a) shows the sealing surface form using rubber O-rings and metal hollow O-rings.

Figure 3-2(b) shows the sealing surface of the trapezoidal groove, which can be equipped with metal octagonal gasket and oval gasket.

Figure 3-2(c) shows the lens pad sealing structure, which is used for the connection of high-pressure pipelines.