What is the difference between ANSI standards and ASME standards flange?

Both ANSI and ASME are important organizations for the industrial heating industry. The ANSI and ASME terms are most common in metal industries. Each of them plays an integral role in setting the norms and standards that govern the industry.

ASME is a standard of the American Society of Mechanical Engineers, one is a national general standard, the ANSI is a mechanical engineering standard; ANSI Flanges and ASME Flanges are the standard flanges designed with specific rules and conditions stated by ASME and ANSI standards. of course, many standards in the ANSI standard refer to the ASME standard flanges.

But many people still don’t know the exact difference between ANSI and ASME flanges. , They don't realize that these organizations are actually two distinct nonprofits.

Here, we will see each in detail and then discussed the main difference between ANSI and ASME flanges.

What is difference Between ANSI and ASME Flanges?

ASME has been defining piping safety since 1922.ASME flanges are widely used to ensure the safe operation of pipelines. In order to better understand ASME flanges, let's first take a look at ASME.

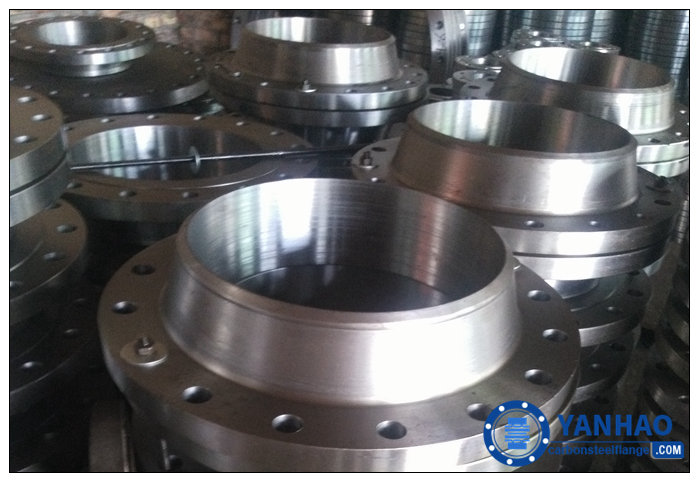

The flange is a device that connects pipes or instruments and plays the role of connection and fixation. Common flanges are made of round steel, and the shapes are divided into flat plates, blind plates, high necks, and flat welds.

It is mentioned that many friends in Flange may not know very well, and we don’t see The standard ASME B16.47 is divided into ASME B16.47 series A and ASME B16.47 series B flange for Blind flange and Weld neck flange. What is the difference between the A-series and the B series in the ASME B16.47 flange standard? How should we choose?

What is meant by ANSI standards?

ANSI is an abbreviation for the American National Standards Institute, a non-profit organization composed of members from a wide cross-section of individuals associated with them in academia, government agencies, businesses, and organizations that have an interest in establishing engineering standards to ensure that products, services, and processes are consistent and predictable for all.

ANSI tends to focus on establishing these standards for the United States, but also works to ensure that companies and individuals get accreditation within these standards. ANSI also focuses on promoting the interests of the United States as the global leader in engineering processes and standards.

What is meant by ASME standards?

ASME is the abbreviation for the American Society of Mechanical Engineers a group of mechanical engineers and representatives from engineering companies–also non-profit–establishing standards and codes for mechanical devices such as boiler components and fasteners as well as actively promoting these standards through education, publications, certifications, and conferences.

ASME focuses on educating and evaluating mechanical engineers to obtain the Professional Engineer (PE) license and focuses more on finding “day-to-day” solutions to mechanical engineering problems.

ASME is the leading international developer of codes and standards, hereafter referred to as standards, associated with the art, science, and practice of mechanical engineering. ... ASME standards are accepted for use in more than 100 countries around the world.

Most of the standards of the American National Standards Institute come from various professional standards. On the other hand, various professional societies and associations can also formulate certain product standards based on existing national standards. Of course, it is not necessary to formulate your own association standards according to national standards. ANSI standards are adopted voluntarily. The United States believes that mandatory standards may limit productivity growth. However, standards quoted by-laws and formulated by government departments are generally compulsory standards.

Of course, it is not necessary to formulate your own association standards according to national standards. ANSI standards are adopted voluntarily. The United States believes that mandatory standards may limit productivity growth. However, standards quoted by-laws and formulated by government departments are generally compulsory standards.

The American National Standards Institute itself rarely sets standards. The preparation of its ANSI standard mainly adopts the following three methods:

1. Relevant units are responsible for drafting, inviting experts or professional groups to vote, and submitting the results to the standard review committee established by ANSI for review and approval. This method is called the polling method.

2. Representatives of the ANSI technical committee and committees organized by other institutions draft the standard draft, all members voted on it, and finally the standard review committee reviewed and approved. This method is called the committee method.

3. From the standards formulated by various professional societies and associations, those that are more mature and of great significance to the whole country, after being reviewed by the ANSI technical committees, are upgraded to national standards (ANSI) and named as ANSI standards And the classification number, but at the same time retain the original professional standard code.

ANSI Flanges

ANSI Flange is an abbreviation of the American National Standards Institute, a private and non-profit organization focusing to make uniformity in voluntary standards used in engineering disciplines. From ANSI’s mission and vision, we can clearly see the organization working for national as well as global industrial standards. The ANSI is more focused on the products, systems, services, and resources of the United States. ANSI was founded on 14th May 1918 by corporations, government agencies, organizations, and academic fields.

ASME Flanges

ASME Flange is an abbreviation of the American Society of Mechanical Engineers, a non-profit and private organization created for bringing uniformity in voluntary standards used in engineering and industrial disciplines. The ASME is mainly focused on setting codes and standards for mechanical devices. They were founded in 1880, after the numerous steam boilers and pressure vessel explosions in various parts of the world.

What is difference Between ANSI and ASME Flanges?

ASME Flanges are based on guidelines and regulations for mechanical devices, while ANSI Flanges are based on standards developed by associations. ANSI flanges are generated using approximately 9500 standards, whereas ASME flanges are produced using 600 codes and regulations for various mechanical devices. The ANSI due process requirements are met by ASME, which is a certified Standards Developing Organization (ANSI). American National Standards are standards that are developed as part of an approved program.

In the metal industry, the terms ANSI and ASME are most commonly used. However, many people are still confused about the differences between ANSI and ASME. They believed that ASME and ANSI flanges are comparable and that there is no distinction to be made between them. That, however, is incorrect. ANSI and ASME Flanges are standard flanges that are developed to satisfy specific ASME and ANSI rules and requirements.

The only major difference between ANSI and ASME is that ANSI accepts procedures, goods, systems, and supplies to be used in the United States, whereas ASME is more likely to be in process of designing mechanical device codes and standards. The ASME team is made of skilled engineers and companies, whereas the ANSI team is made up of government agencies, organizations, and individuals. ANSI is a private, non-profit organization that oversees the quality of goods and services in the United States. Whereas ASME is a leading private organization that develops mechanical industry standards and codes. The main aim of ASME is to look at developing solutions for mechanical problems, while ANSI put its attention on solidifying the US position in the market.

Although ANSI doesn’t come with guidelines, it does monitor their planning and application by institutions. For mechanical devices such as boiler components, elevators, fluid quantification in closed conduits, fasteners, and other tools, ASME has developed over 600 codes and standards that cover all technical aspects.

Pipe flanges that are made to standards are called out by ASME B16.5 or ASME B16.47, and MSS SP-44. They are typically made from forged materials and have machined surfaces. ASME B16.5 refers to nominal pipe sizes (NPS) from 1⁄2" to 24". B16.47 covers NPSs from 26" to 60". Each specification further delineates flanges into pressure classes: 150, 300, 400, 600, 900, 1500 and 2500 for B16.5, and B16.47 delineates its flanges into pressure classes 75, 150, 300, 400, 600, 900. However, these classes do not correspond to maximum pressures in psi. Instead, the maximum pressure depends on the material of the flange and the temperature. For example, the maximum pressure for a Class 150 flange is 285 psi, and for a Class 300 flange, it is 740 psi (both are for ASTM a105 carbon steel and temperatures below 100°F).

Don’t let these acronyms confuse you. Whether you need ANSI flanges or ASME flanges, YANHAO is the company you should turn to for your flanges needs.

If you want to learn more about these ANSI and ASME Flanges Contact Us today. We provide complete information for free.

Call us at (0086) 15303178205 or drop us an email at sales@yanhaocn.com. We provide complete information for free.