Alloy Steel Flange

YANHAO is a leading manufacturer of alloy steel flange. Alloy Steel Flanges are made in different steel alloys. The flanges vary in dimensions and types. There are ½ inches through 48 inches of nominal diameter sizes of flanges.

Alloy steel flange standards and specifications

| Specification : | Alloy Steel Flanges |

| Pressure Rating Table of ANSI Standard: | Class 150 LBS Flanges, Class 300 LBS Flanges, Class 600 LBS Flanges, Class 900 LBS Flanges, Class 1500 LBS Flanges, Class 2500 LBS Flanges |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Connect Type Type: | LJF, RF, FF, RTJ, LMF, SMF |

| Design For Size: | EN Flanges, ASME Flanges, DIN Flanges, JIS Flanges, ANSI Flanges, BS Flanges, PN Flanges |

| Flange Machining Equipment: | Bending machine, Pushing Machine, Sand-blasting machine, Press machine, electric bevelling machine, etc |

| Alloy Steel Flanges Standards: | JIS Standard Flanges, EN Standard Flanges, DIN Standard Flanges, ASME B16.5 Flanges, ASME B16.47 (Series A, Series B) Flanges |

| Production Process: | machined Heat treated Forged |

| Coating Flange Faces : | Cold and Hot Dip Galvanized, Anti-rust Paint, Zinc Plated, Yellow Transparent, Oil Black Paint |

| Test | We at ensuring that all our materials go through strict quality tests before dispatching them to our clients. UI ultrasonic flaw detector Magnetic particle detector Direct reading Spectrograph X-ray detector Hydrostatic testing machine |

| Certificates | We can provide the following certificates: Raw Materials Certificate 100% Radiography Test Report Third-Party Inspection Report, etc FERRITE CONTENT as per norms if requested by clients. |

| Supporting Flange Material: | Gasket, Ring Joint, Flange Bolts |

| Flanges Marking | All Flange are marked as follows: Manufacturer’s or Supplier Name, Dimension, Class, Size, Material, Bore, Heat No. |

| Common Types of Flange : | Flanges 150 LB WNRF Class 300 RTJ 600# BLRF Class 900 SORF |

| Application: | Off-Shore Oil Drilling Companies Nuclear Power Plant Oil And Gas Industry Gas Processing Specialty Chemicals Pharmaceuticals Pharmaceutical Equipment Chemical Industry Water Pipeline Industry Sea Water Equipment Heat Exchangers Condensers Pulp and Paper Industry Fabrication Industry |

Introduction to raw materials of alloy steel flange

Alloy steel and carbon steel are two types of steel. Alloy steel is metal alloys of iron, carbon, and high amounts of other elements. The other elements present in it typically include manganese, silicon, nickel, titanium, copper, and chromium. These elements are called alloy elements because these elements are mixed together to form an alloy. The purpose of adding these elements is to improve the properties of steel.

Carbon steel flanges and alloy steel flanges are different kinds of material grades for flanges, although both are extremely common. Alloy steel comes with a variety of elements depending upon future applications. The carbon steel also known as iron-carbon alloy contains less than 2% carbon WC. It usually contains small amounts of carbon, phosphorus, sulfur, manganese, and silicon in the mix.

The main difference between alloy steel and carbon steel is that alloy steel has high amounts of other elements apart from iron and carbon whereas carbon steel has trace amounts of other elements apart from iron and carbon.

In the case of alloy steel, elements like molybdenum, manganese, chromium, nickel, vanadium, silicon, and boron are used to form a different chemical composition. Generally, alloy steels are of the higher nickel variety and the term is used to distinguish them from regular stainless or low chrome materials.

Application of alloy steel flange

Alloy steel flanges come in a broad range of applications. They are widely used in various industries including petrochemical, oil and gas, power generation, bulk liquid transportation, chemicals, pharmaceuticals, pulp and paper manufacturing, textiles, and others.

Alloy steel flanges are classified into two categories, high alloy steel flanges, and low alloy steel flanges.

Low alloy steel flanges have applications in a wide range of industries due to their cost-effectiveness. Low Alloy Steel Flanges contain about 0.05 – 0.25% of carbon along with up to 2.0% manganese. Low alloy steels contain trace quantities of alloys such as niobium, nitrogen, vanadium, copper, nickel, chromium, titanium, calcium, molybdenum, rare earth elements, or zirconium.

Low alloy steel flanges have applications in military vehicles, construction equipment, ships, pipelines, pressure vessels, and oil drilling platforms.

High alloy steel flanges are widely applied in various applications due to their structural components, automotive applications, chemical processing equipment, corrosion resistance, and superior hardness. In order to strengthen the Chromium AS Flanges, its alloy has added elements i.e. Copper, titanium, vanadium, and niobium.

Advantages of alloy steel flange

1. Corrosion resistance

2. Powerful parts

3. Efficient at high temperature

4. Heat dissipation properties

5. Durable

6. Tough

7. Lightweight

8. High tensile strength

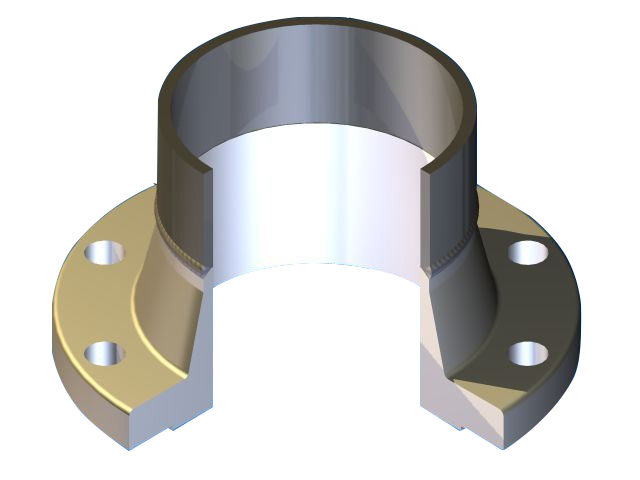

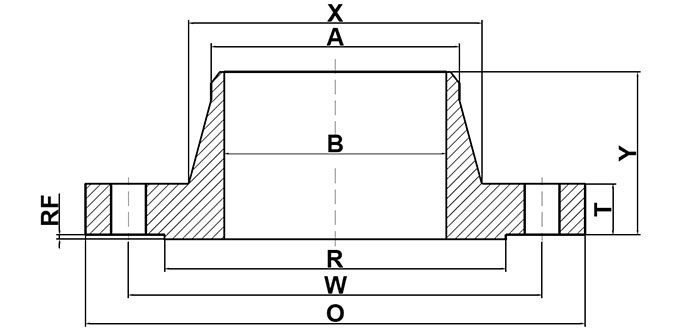

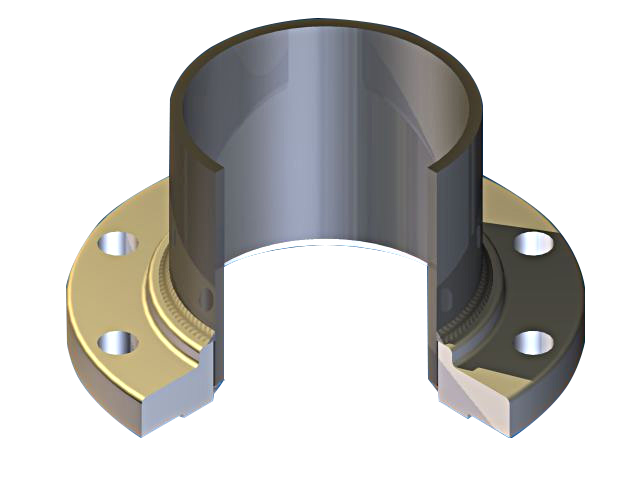

Types of Alloy Steel Flanges

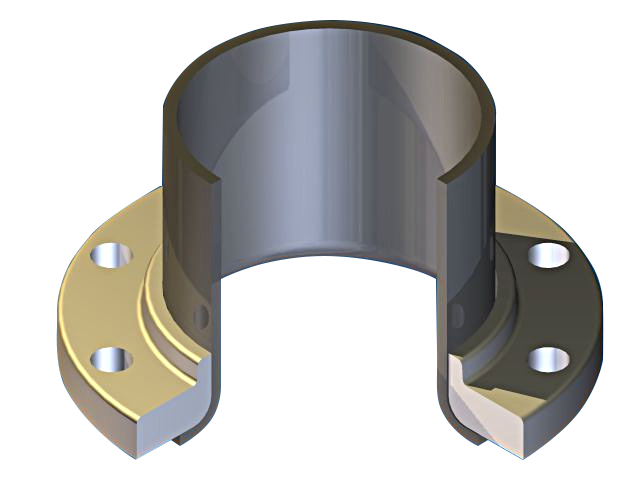

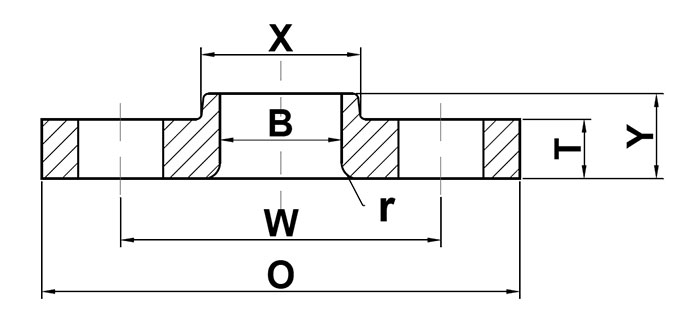

| TYPES | ASME/ANSI B16.47 Series A Weld Neck Flange | ASME/ANSI B16.47 Series B Weld Neck Flange | ASME/ANSI B16.5 Weld Neck Flange |

| SIZES | 26″-60″ | 26″-60″ | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900 | class75, 150, 300, 400, 600, 900 | class150, 300, 400, 600, 900, 1500, 2500 |

| MATERIAL | ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22 | ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22 | ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22 |

| TYPES OF FLANGE FACES | 1/16″ raised face | 1/16″ raised face | 1/16″ raised face |

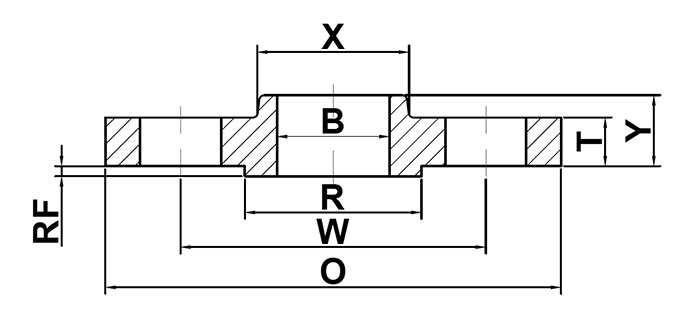

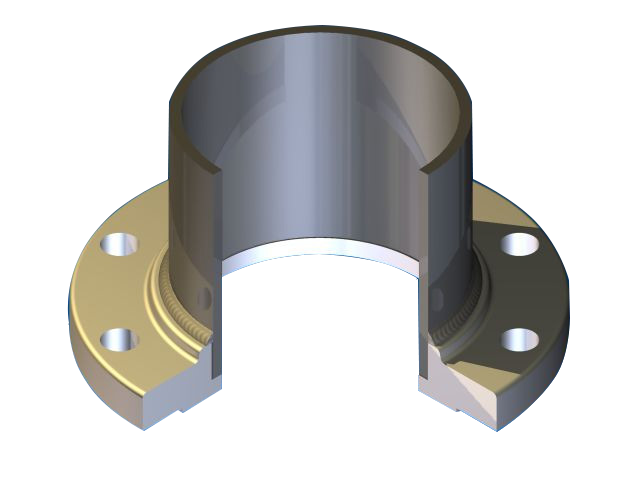

| TYPES | Slip-On Flanges |

| SIZES | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900, 1500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face |

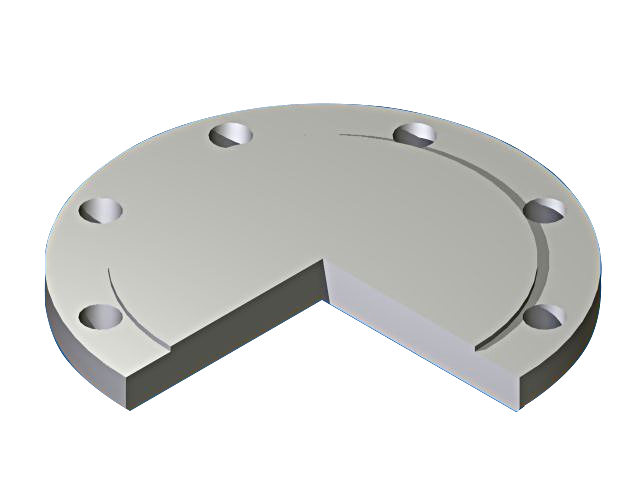

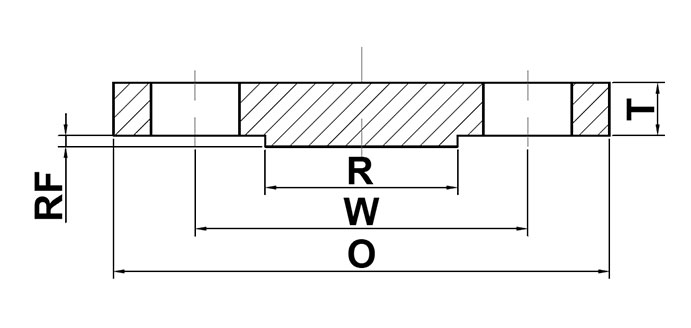

| TYPES | ASME/ANSI B16.47 Series A Blind Flanges | ASME/ANSI B16.47 Series B Blind Flanges | ASME/ANSI B16.5 Blind Flanges |

| SIZES | 26″-60″ | 26″-60″ | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900 | class75, 150, 300, 400, 600, 900 | class150, 300, 400, 600, 900, 1500, 2500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face | 1/16″ raised face | 1/16″ raised face |

| TYPES | Lap Joint Flanges |

| SIZES | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900, 1500, 2500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES | Socket Weld Flanges |

| SIZES | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900, 1500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face |

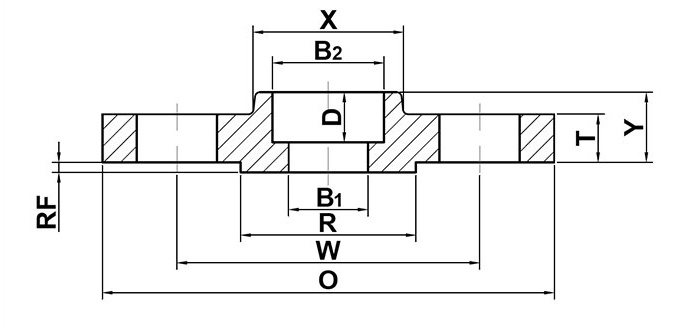

| TYPES | Threaded Flanges |

| SIZES | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900, 1500, 2500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face |

Alloy Steel Flanges Price List

Alloy Steel Flanges

US $0.5-1000 / Piece (FOB Price)

Alloy Steel Pipe Flanges

US $300-500 / Ton (FOB Price)

Alloy Steel Weld Neck Flanges

US $1-900 / Piece (FOB Price)

ASTM A182 alloy steel plate flanges

US $0.5-1000 / Piece (FOB Price)

alloy steel pipe Flanges

US $1-300 / Piece (FOB Price)

Alloy Steel Pipe Flanges Packaging

All our Alloy Steel Flange are manufactured in accordance with international standards. Alloy Steel Pipe Flange are packaged to ensure that there is no damage during transit. In the case of exports, standard export packaging is done in wooden cases. All Alloy Steel Plate Flanges are marked with Grade, Lot No, Size, Degree, and our trademark. On special requests, we can also, make custom marking on Alloy Steel Flanges.

YANHAO is known to manufacture, export, supply, and trade unit of Alloy Steel Pipe Flanges, which are offered in diverse and personalized order sizes, designs, and shapes for our esteemed clienteles. We also offer the same in different grades.

These Alloy Steel Slip On Flanges can be machined, shot–peened, and polished in as–built or stress-relieved states if required, where rust is the obvious visible evidence of corrosive activity.